感应加热弯管(钢管)“屈服强度”和“抗拉强度”偏低原因分析

2023-05-04 来源:飞速影视

感应加热弯管屈服强度和抗拉强度偏低原因分析Cause Analysis of Low Yield Strength and Tensile Strength of Induction Heating Elbow

针对某管厂试制的弯管出现的过渡区外弧侧管体屈服强度和抗拉强度低于标准要求的情况进行了 分析。 对弯管取样进行了 力学、 化学及金相分析和试验。 结果表明, 弯管过渡区外弧侧管体屈服强度和抗拉强度偏低是因为该部位起始加热温度偏低(低于 950 ℃), 其淬火、 回火后组织以铁素体居多 , 降低了 抗拉强度, 使其低于标准要求。 建议弯管开始推制时, 适当 提高加热温度,使过渡区的力学性能达到要求。

关键词: 焊管; 感应加热弯管; 钢管性能,管道,钢管,锅炉钢管,锅炉管道,高温钢管,锅炉管材,屈服强度,抗拉强度,感应加热,弯管.

In this paper, the situation of yield strength and tensile strength of the external arc side pipe in the transition zone of trial production bend which were below the standard requirements were analyzed.By the mechanics, chemistry and metallographic testing, the results show that the situation was because that the origin heating temperature (less than 950 ℃) was lower, the ferrite was in the majority after quenching and tempering , and the tensile strength was reduced to below the standard requirement. It was suggested that the origin heating temperature should be increased when the bend was pushed, the mechanical properties of the transition zone can meet the standards requirements. Key words: welded pipe; induction heating bend; yield strength; tensile strength.

相关影视

度日勉强

2023/其它/剧情片

勉强度日

2023/其它/剧情片

钢管侠

2015/大陆/动作片

我管漂亮你管帅动态漫画第1季

2019/大陆/国产动漫

春原庄的管理人

2018/日本/日韩动漫

关于现在这里发生的危机和我的好感度

2021/日本/日本剧

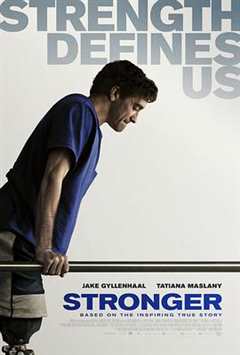

生命因你更强

2017/美国/剧情片

分手进度百分之99动态漫画

2023/大陆/国产动漫

合作伙伴

本站仅为学习交流之用,所有视频和图片均来自互联网收集而来,版权归原创者所有,本网站只提供web页面服务,并不提供资源存储,也不参与录制、上传

若本站收录的节目无意侵犯了贵司版权,请发邮件(我们会在3个工作日内删除侵权内容,谢谢。)

若本站收录的节目无意侵犯了贵司版权,请发邮件(我们会在3个工作日内删除侵权内容,谢谢。)

www.fs94.org-飞速影视 粤ICP备74369512号